Compost Filter Socks

Compost Filter Socks (CFS)

CFS serve as a sediment control practice that improve soil building when the sock is cut and compost is spread as mulch, or incorporated into native soils. In this capacity, compost can improve top soil structure and cohesion, improve filtration capacity and reduce invasive plant growth, and possibly bind pollutants such as hydrocarbons, phosphorus, and heavy metals in runoff. CFS with potential pollutants shall be properly disposed of in an approved landfill.

CFS are deliverable to the jobsite “pre-filled” and are situated on standard wood pallets 40X48. CFS standard dimensions are 8-inch and 12-inch in diameter and 20-feet in length, however, CFS can be made as long as necessary. Longer length CFS can be installed with a skid steer, backhoe, or like machinery.

The installing contractor shall determine the best method for the existing site and its conditions. CFS should not be drug, pulled, or run over.

Installation

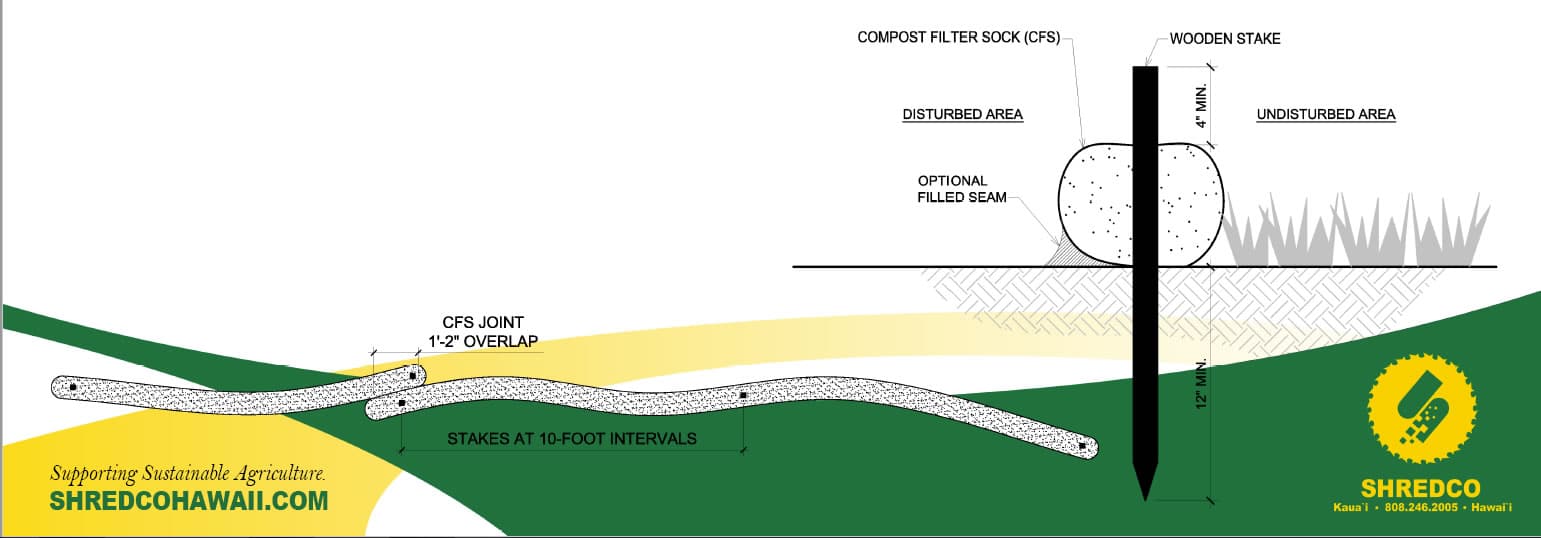

CFS should be placed on level ground, in sections running perpendicular to the runoff flow direction. Loose material (soil, mulch, sand, or like fill) may optionally be placed along the upslope, filling the seam between soil surface and the sock to improve sedimentation retention. Hardwood stakes shall be installed through the middle of continuous 10-foot intervals. CFS can be staked on the downslope side with stakes tilted downward wedging the CFS in place. Staking depth for sand clay and silt loam soils shall be 12-inches. In the event staking is not possible (when placed on hard surfaces) heavy concrete blocks shall be used behind CFS to help stabilize during rainfall/runoff. Where two sections meet j-hook higher elevation end, or side overlap one to two feet and tightly side butt. Stake through each end and add loose material as needed.

CFS must be occasionally moved or must run diagonal to grade. CFS sectional installation allows period j-hooks at section ends and added loose material as needed. This prevents parallel unchecked water flow that can undermine the CFS.

Operation and Maintenance

Inspect CFS every seven days and within 24-hours after a storm where rainfall is 0.5-inches or greater.

Accumulated sediment shall be removed when the capacity for sediment storage has been reduced by half. Sediment that has been removed shall be placed such that it will not reenter the system.

The contractor shall functionally maintain the CFS whenever tears, splits, unravelling or compressed compost is apparent, immediately repair the damage and add supplemental best management practices as necessary. Remove debris accumulated on the CFS.

Removal

All sediment accumulation at the CFS shall be removed and properly disposed of before removal.

CFS shall remain in place and removed when final vegetation is stabilized. Compost material to be dispersed onsite as determined by the engineer.

Material

The compost used in CFS meet all local, state, and federal quality requirements.

Our compost is tested under the “Test Methods for the Evaluation of Composting and Compost” (TMECC).